Quick clarity before we dive in: BIM dimensions (3D/4D/5D/6D) describe what kind of information you manage (geometry, time, cost, operations). LOD (Level of Development) describes how reliable/detailed that information is (100–500). They work together, but they’re not the same thing.

3D BIM – Geometry & Location

3D is your coordinated model-the place where architecture, structure, and MEPF live together so clashes surface before site. It drives drawings, shop details, and early quantities for bim and construction teams. On a hospital project, a federated model might reveal a cable tray clipping a sprinkler main; you tweak elevations and fittings in the model and avoid a weekend of rework. For a deeper dive on detail targets, see our guide on Levels of Development (LOD) in BIM.

- Use it for design coordination, clash resolution, drawings, takeoffs.

- Two pitfalls to dodge: over-modeling at LOD 400 “because we can,” and late federation that snowballs into clashes.

Related reading: What Is BIM in Construction?

4D BIM – Time & Sequencing

4D links the model to your schedule so the plan is visible-and testable-before anyone mobilizes. It’s not a “movie”; it’s a decision tool. Think of a data center fit-out where raised floor, trays, and rack deliveries collide. A quick 4D run exposes the conflict, you re-sequence, and you don’t lose your weekend. For document control that supports the plan, see BIM 360 Document Management.

- Use it for phasing, site logistics (cranes, laydown, access), weekly look-aheads.

- Key discipline: break work by zone/system; don’t hide everything in one “MEP install” task.

5D BIM – Cost & Quantities

5D ties model quantities to cost items so budgets move with design. When a façade switches from ACP to terracotta, areas and line items update; the owner sees CapEx deltas in time to choose, not after procurement. Confidence comes from clean classifications, explicit measurement rules, and versioned cost libraries-especially if you engage in BIM outsourcing services for surge estimating support.

- Use it for early budgets with stated confidence, VE comparisons, and change control.

- Publish your LOD and assumptions; dirty families and vague types = garbage in, garbage out.

6D BIM – Operations & Facility Management

6D captures asset data you’ll actually use after handover: tags, serials, warranties, O&M links-tied to spaces and systems. In a university lab, scanning a QR on an autoclave should pull up its model location, isolation diagram, warranty end date, and last service-no hunting, no guesswork. If you’re planning the handover, align 6D requirements early with architectural drafting services and MEP BIM services so those fields are captured during design/fabrication. Read: How BIM Enhances Facility Management.

- Use it for preventive maintenance, faster troubleshooting, and long-term capital planning.

- Keep it lean: asset ID, system, space, make/model, serial, warranty, PM frequency, O&M link, vendor contact-and integrate with the owner’s CMMS.

Where LOD Fits (keep it practical)

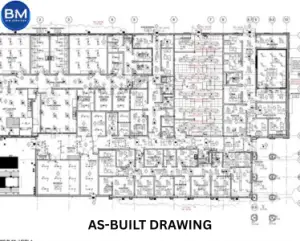

Use LOD 100–200 for concept and rough 5D ranges, LOD 300 for coordinated design and reliable clash checks, LOD 350–400 where you fabricate and install (this is where MEPF services really earn their keep), and LOD 500 for verified as-built seeds. Rule of thumb: model to decisions, not vanity-raise LOD only where it changes scope, cost, or sequence.

Also see: Architectural BIM Services vs Traditional CAD Design

One Scope, Four Dimensions (short walkthrough)

Replacing a central chiller in a live hospital: 3D confirms geometry, access, and rigging paths; 4D sequences isolation → weekend changeover → crane day → commissioning; 5D rolls quantities into line items and compares high-efficiency vs. base chiller CapEx/Opex; 6D locks in serials, warranties, PM intervals, and a QR that opens the exact CMMS asset.

Implementation Essentials

Get the finish line defined in the BEP and contract-what 4D/5D/6D deliverables are due, when, and to what standards. Standardize parameters (systems, zones, asset IDs) so 4D links, takeoffs, and FM fields don’t crumble later. Use 4D in weekly coordination, publish 5D assumptions and confidence on every estimate, and keep 6D lean enough that FM will actually maintain it.

- Three must-haves: a clear data-drop plan, governed cost libraries, and live CMMS integration.

Final take

Use the dimensions where they change decisions: 3D to build right, 4D to build in the right order, 5D to spend right, 6D to operate right. Keep LOD aligned to milestones, and weave in architectural bim modeling, architectural drafting services, and mep bim service where they add measurable value-not noise.