portfolio

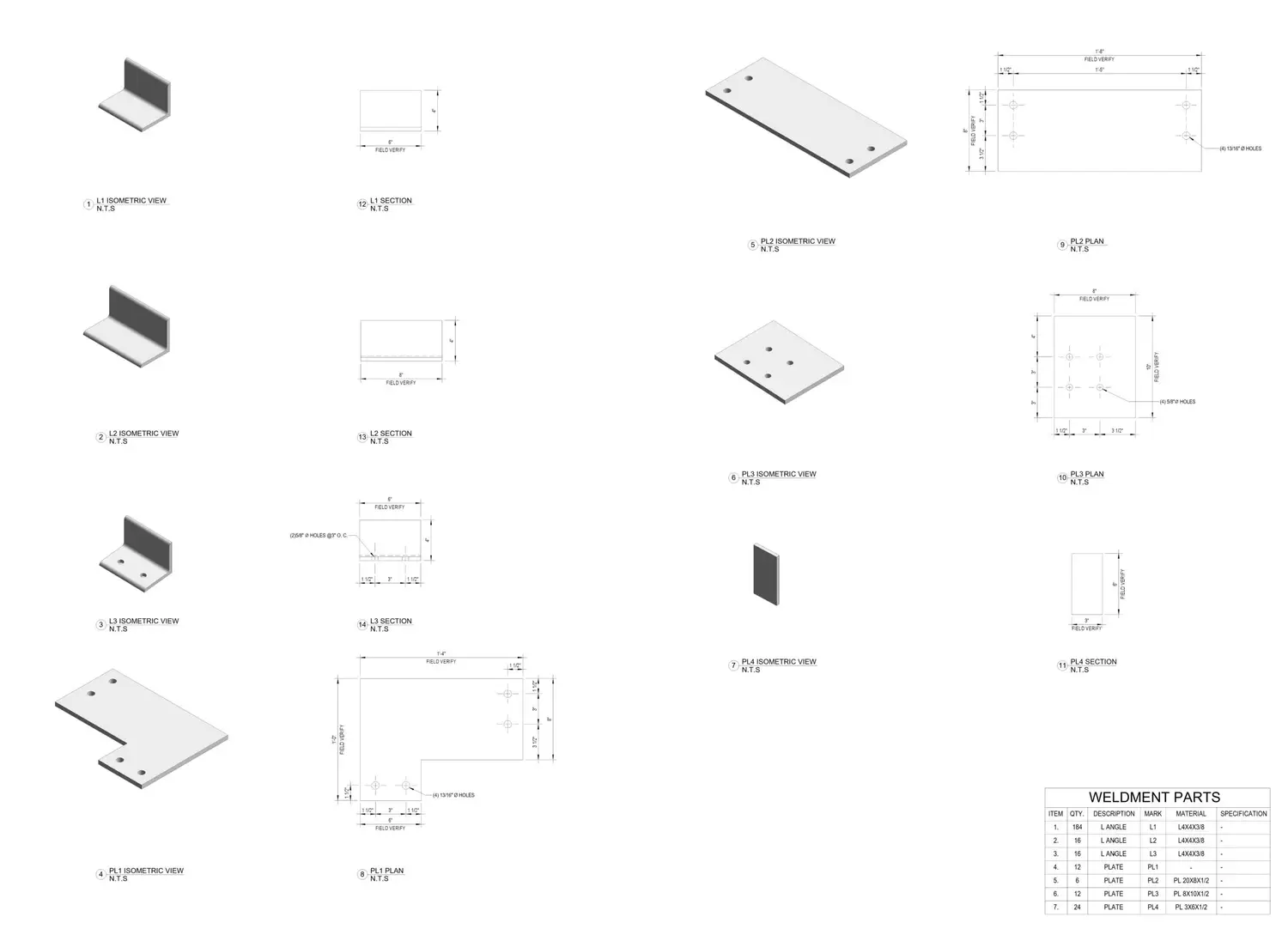

Tesla Giga Texas – Cell Phase 2 (Elevator)

- Project Area:

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 350

- Trades Covered: SHOP DRAWING

- Software: REVIT

- Verticals: 2023

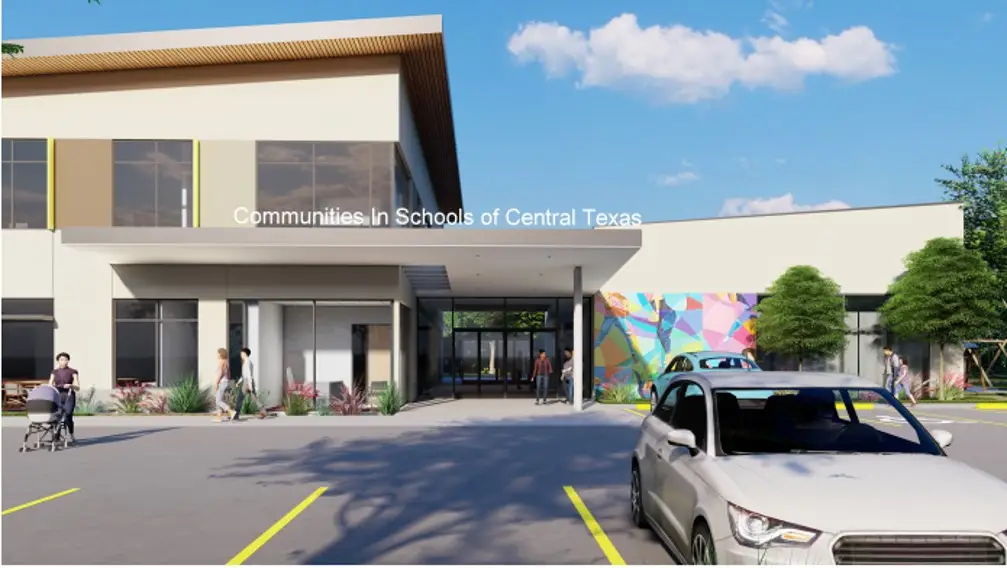

Communities In Schools Central Texas

- Project Area: 6085 sq ft

- Architect: N/A

- Engineer: N/A

- Contractor(S): BIM SERVICES LLC

- Owner: N/A

- LOD: 350

- Trades Covered: Plumbing, Shop Drawing, As -Built

- Software: Revit Fabrication 2021

- Verticals: Plumbing

Challenges and Solutions

Challenge 1: Ceiling Space Constraints

- Issue:

- Condensate drain pipe clashed with ceiling and fire protection pipes below ceiling.

- Solutions:

- Drop ceiling to accommodate pipes.

- Use a pump for condensate drain at units.

- Reduce pipe run length by dropping pipe into nearest mop sink.

Challenge 2: Exposed Plumbing Risers in Rooms

- Issue:

- Plumbing risers exposed or in the middle of rooms per design.

- Solution:

- Coordinate and reroute plumbing pipes to conceal or relocate them appropriately.

Mardela Middle & High School

- Project Area: 118,993 sq ft

- Architect: N/A

- Engineer: N/A

- Contractor(S): Not specified

- Owner: Not specified

- LOD: 400

- Trades Covered: Plumbing, Shop Drawing, As-Built

- Software: Revit Fabrication 2021

- Verticals: Plumbing

Challenges and Solutions:

Challenge 1: Coordination in Corridors

- Issue:

- Congested corridors with units, refrigerant pipes, light fixtures, and fire protection (FP) systems.

- Solution:

- Relocated units to adjacent rooms to clear space in corridors, resolving clashes with other trades. Changes were submitted for approval.

Challenge 2: Concurrent Modeling and Fieldwork

- Issue:

- Modelling, coordination, and drawing submissions overlapped with fieldwork, posing challenges for accuracy and documentation.

- Solution:

- Implemented a ‘Deliverable Log’ to track revisions and provide links to the latest drawings/models. Mobilised resources to ensure timely and accurate delivery of multiple deliverables to the client.

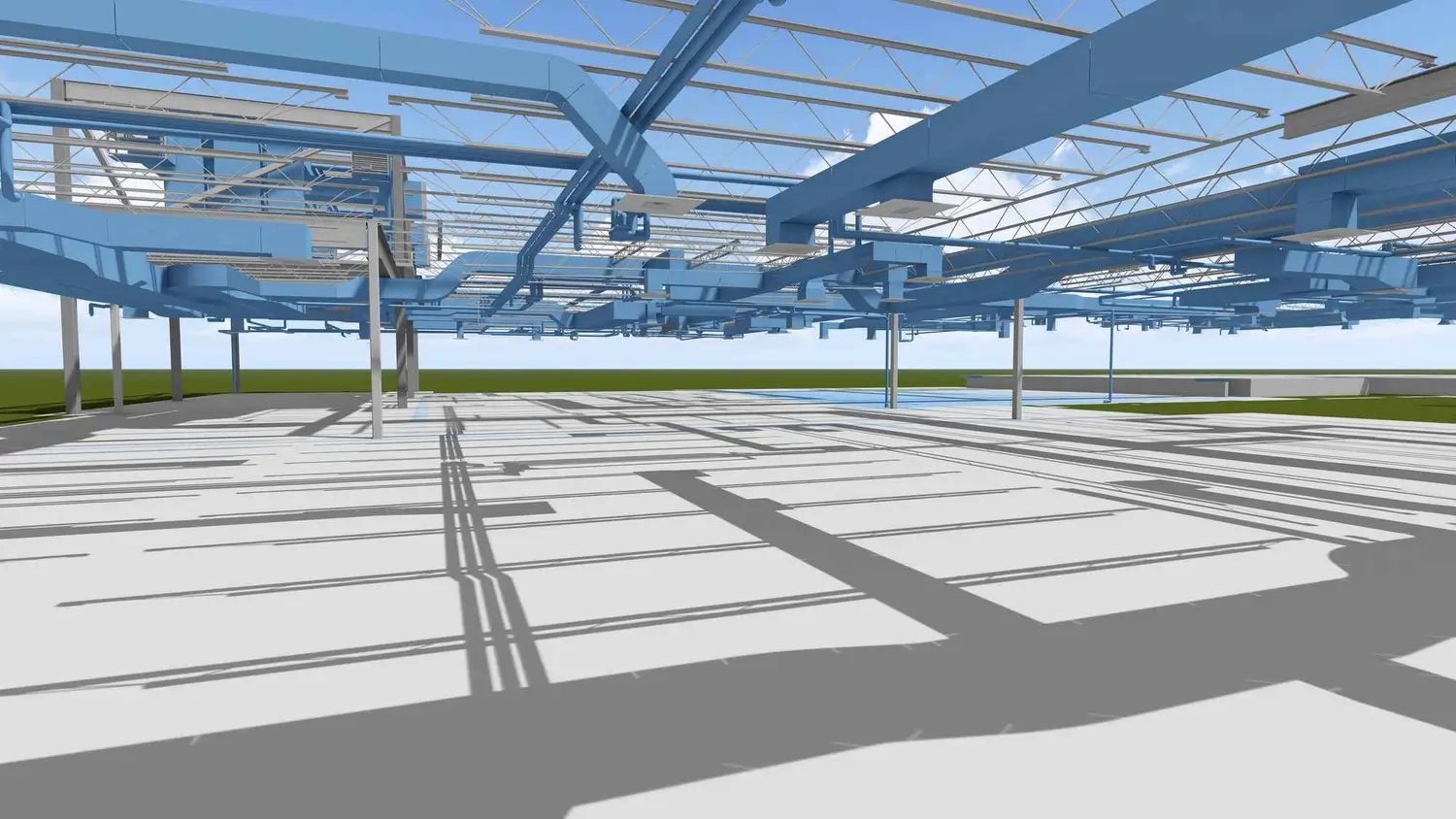

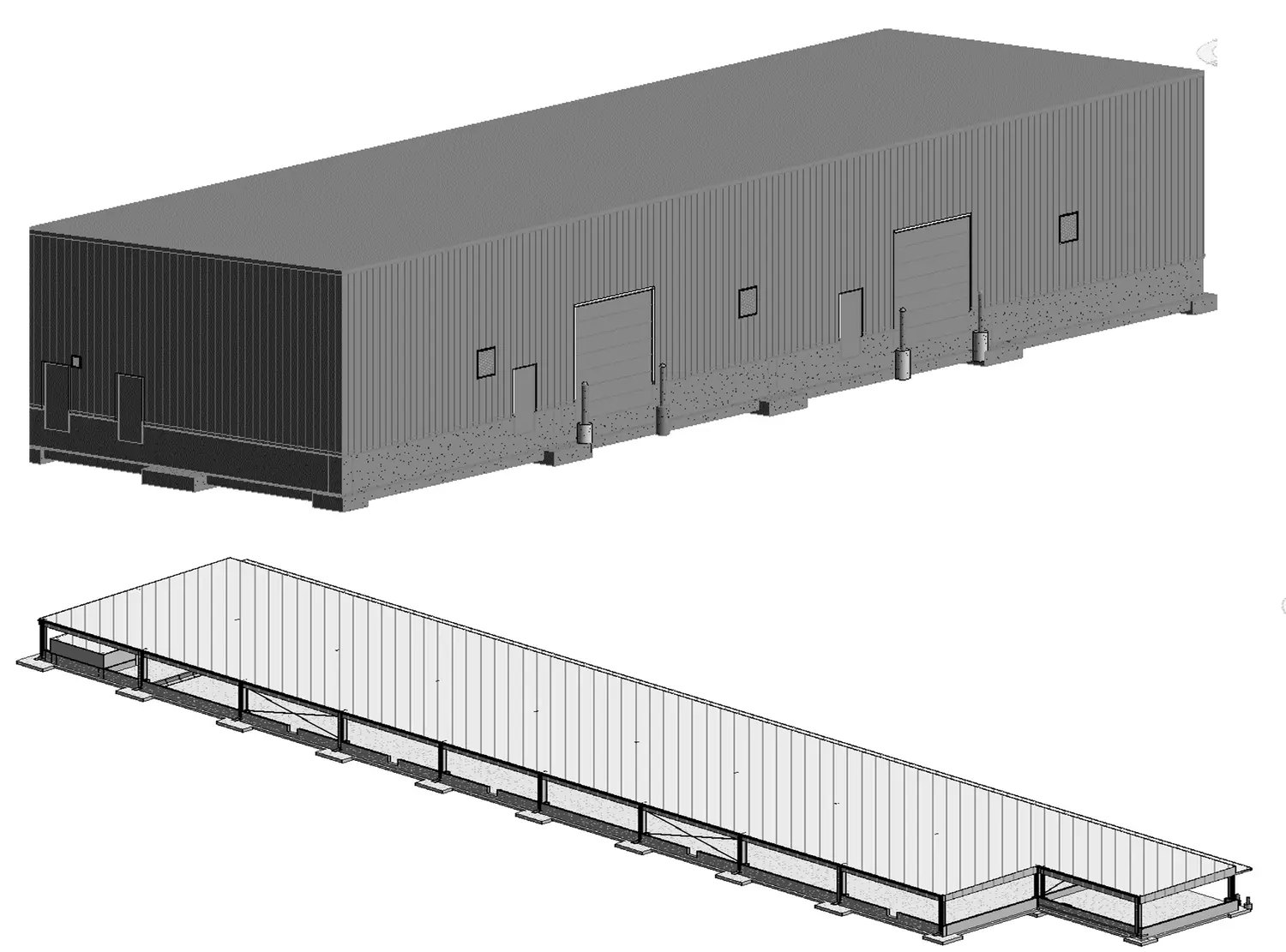

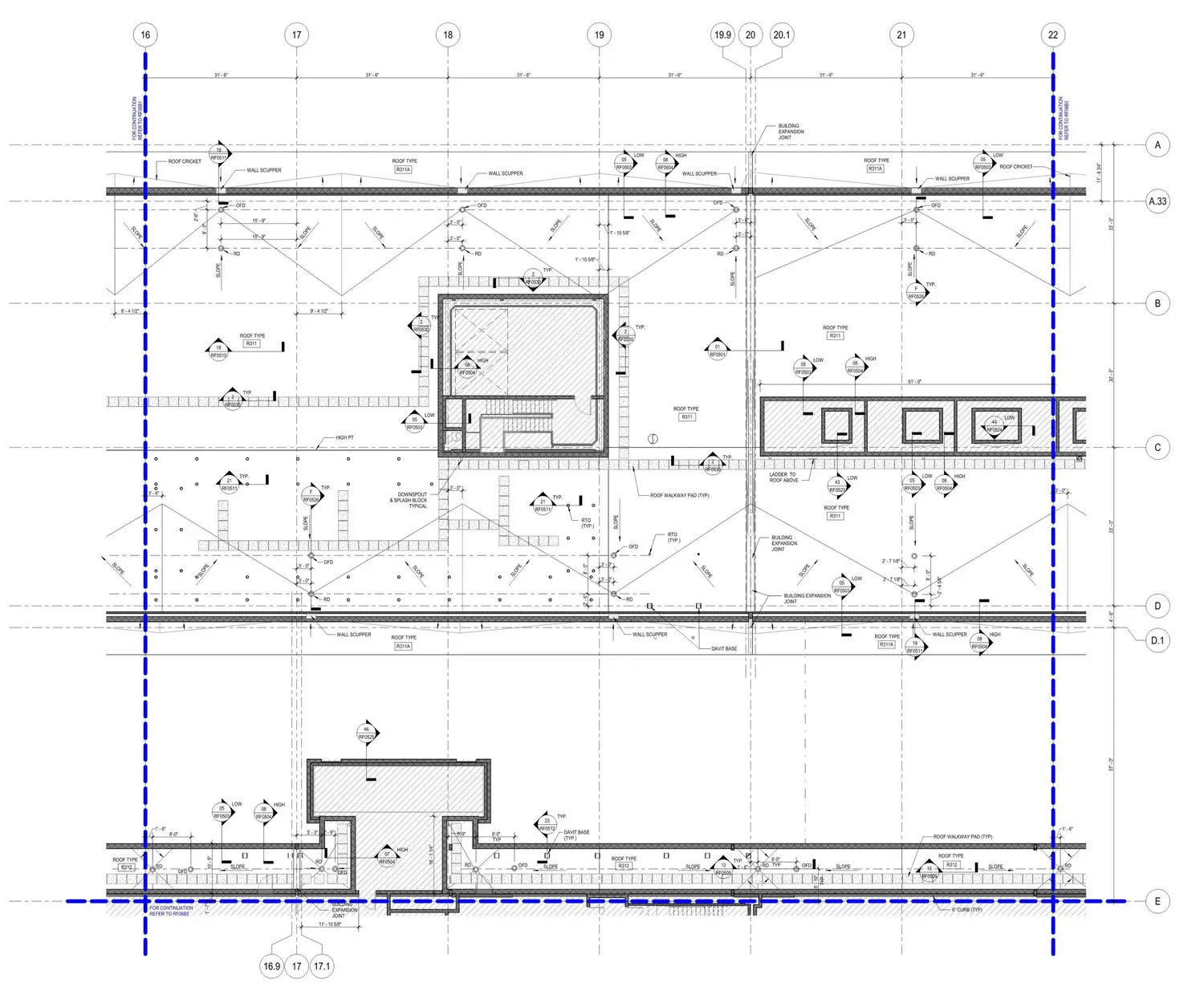

Combined Hazardous Waste Storage

- Project Area: 22800 sqft

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 350

- Trades Covered: SHOP DRAWING

- Software: REVIT

- Verticals: 2021

VA Medical Center

- Project Area:

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 400

- Trades Covered: SHOP DRAWING

- Software: REVIT

- Verticals: 2021

Momentum Apartment

- Project Area:158,400 sq. ft.

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: BOULDER VENTURES INC.

- LOD: 350

- Trades Covered: MECHANICAL

- Software: Revit Fabrication 2020

The Nest Rio Granade

- Project Area: 175,366 sq. ft.

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: SLC RDA

- LOD: 350

- Trades Covered: Fire Protection, Shop Drawing

- Software: Revit Fabrication 2021

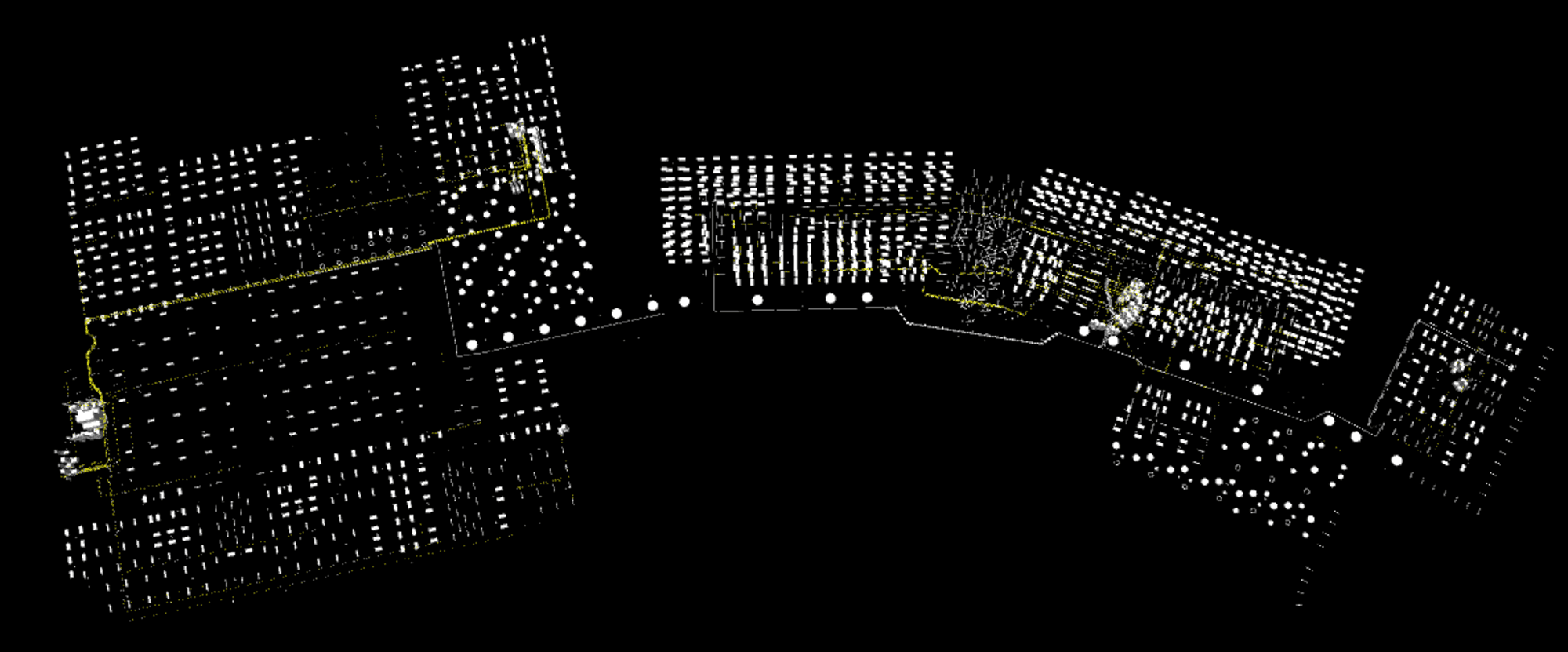

Universal Studios

UNIVERSAL STUDIOS

- Project Area: 541 acre

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 500

- Trades Covered: Site Electrical Utilities

- Software: Revit Fabrication 2022

- Verticals: Electrical

Challenges and Solutions:

Challenge 1: Coordinating area development

Solution: The sheer vastness needed to be coordinated with tones of conduits and handholds along with multiple trades was extremely challenging. With multiple elements and constant construction on site, keeping a log and tab on the changes is a humongous task. Having a thorough schedule and timeline helps keep things working in a smooth flow and deliverables sent on time. Eyes on the field and data received being incorporated on a timely basis are the keys to having successful coordination on a live site work.

Challenge 2: Modeling As-builts along with coordination

Solution: Along with the coordination of Electrical elements and conduits, the same is being installed and constructed on-site. Having to model the proposed and then revise the same to as-built with the site data is a time-consuming task. Keeping the model updated and not having duplicate data as much as possible is the goal. To achieve the same, we have segregated the proposed and As-built models to have as much of a clean slate for the inputs and constantly send the proposed data on-site for installation.

Frost Bank-Prosper

- Project Area: 61,547 sq. ft.

- Architect: Hahnfeld Hoffer Stanford Architects

- Engineer: Moose Engineering

- Contractor(S): SpawGlass

- Owner: Frost Bank

- LOD: 350

- Trades Covered: Site utility(Plumbing)

- Software: Revit Fabrication 2023

Challenges and Solutions:

- Issue:

- Changes in Invert Level & Slope of drain pipes, to accommodate TDI connections with Drain pipes

- Solution:

- After completion of trade clash coordination we were given time-bound architectural changes along plumbing lines raiser changes which was a challenge to coordinate the trades all over again. A quick turnaround on the revision of the BIM model while simultaneously working on clash coordination helped. Keeping up with the design changes at the last minute and sending deliverables on time was a high task. Having a dedicated team for BIM modeling and coordination supported to speed up the completion.

Classical Education Building At Hillsdale College

- Project Area: 19662 sq. ft.

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 350

- Trades Covered: PERMIT DRAWING

- Software: REVIT, AutoCAD, 3ds Max

- Verticals: 2021

Gustin Cottage Roberts Island

- Project Area: 1276 sq. ft.

- Architect: N/A

- Engineer: N/A

- Contractor(S): N/A

- Owner: N/A

- LOD: 350

- Trades Covered: PERMIT DRAWING

- Software: REVIT, AutoCAD, Lumion

- Verticals: 2021

Mc Neil Home Addition

- Project Area: 2500 square-foot

- Architect:

- Engineer:

- Contractor(S):

- Owner:

- LOD:

- Trades Covered: Architecture City Permit

- Software: Chief Architect

- Verticals: Premier X15